CMM Inspection Services

About

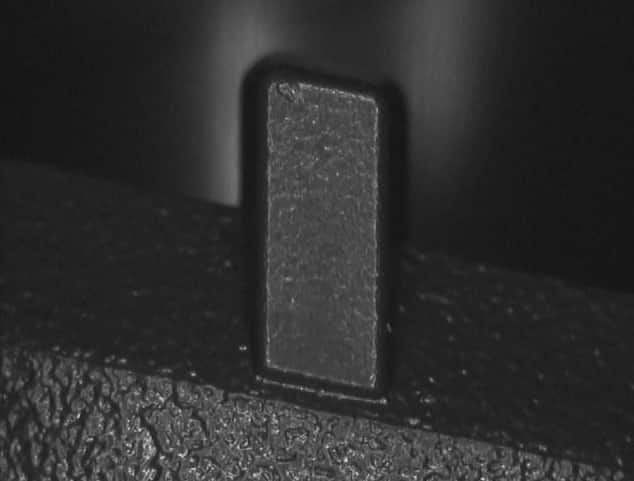

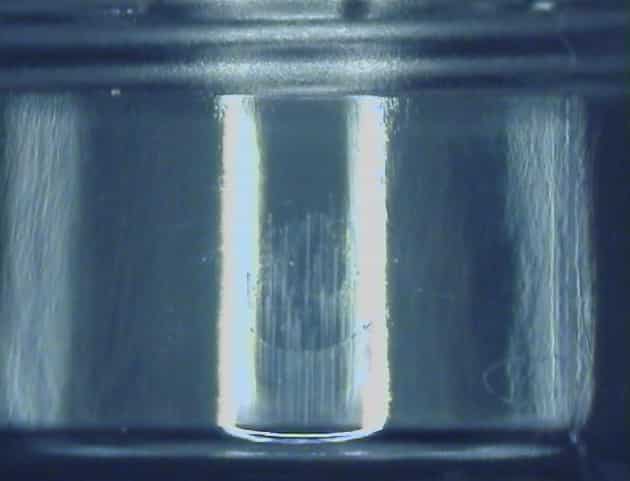

A visual inspection is the first step in identifying part issues across any and all processes of manufacturing. A visual inspection report can be provided to demonstrate molding related part issues. With 3D ProScan’s experience in the injection molding industry, we can easily identify issues such as Flash, Gate Vestiges, Mis-Match, Sinks, Voids, Burns, and many other typical issues that arise when dealing with injection molded parts.

How it Works

Based on prints and customer supplied visual guidelines, 3D ProScan uses the best available technology to locate part issues. We then create a power point presentation highlighting all of the errors found throughout every cavity that required inspection. We use Vision Systems, Optical Comparators, and Microscopes to measure and visualize each part issue as well as capture accurate images of any and all defects.

Visual Inspection Report Examples